Making Lean Work – Capturing Your Continuous Improvement Ideas

By

Rich Sutherland

·

2 minute read

By

Rich Sutherland

·

2 minute read

Continuous improvement is a self-explanatory process, in that it’s all about making positive changes on an ongoing basis. However, rather than focusing on major shifts in how your company operates, continuous improvement takes the form of small changes that can be made quickly and usually with very little or even no cost to the business.

In this blog we look at how to capture your continuous improvement ideas and implement them to full effect.

You need an eye for detail

Due to continuous improvement being about small changes, you need to look at your processes and communication methods in detail. A fleeting glance may give the appearance that everything is flowing at peak performance, whereas an in-depth analysis will present multiple opportunities for simplification, optimisation and improvement.

Small wins are as valuable as big wins

It’s imperative that your employees understand how Lean principles work and why small wins are so important. In the same way that minor faults and constraints can cascade to create large problems, small wins have a positive cumulative effect.

These visible enhancements to processes also make staff feel more empowered, leading to a culture of continuous improvement being firmly embedded across the board.

Use visual management tools

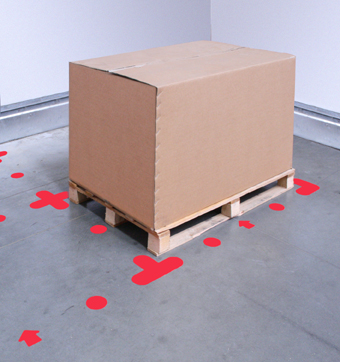

There are many visual management tools available that will help you to change your business for the better. One example is using visual management boards and magnetic overlays to carry out value stream mapping, which will help you to identify and remove sources of waste.

Another example is to install shadow boards, cleaning stations and lock out boards that ensure equipment is always returned to its rightful place. These simple and affordable additions will bring instant results and show your employees how taking responsibility over their daily actions can significantly improve the way their departments perform.

Get everyone involved

The best ideas don’t always come from the top and can in fact be found at every level of your company’s hierarchy. The most common problem is that many employees either won’t feel the motivation to suggest new ways of working or believe that it isn’t their place to do so. That’s why encouraging conversations and welcoming suggestions is imperative, as it could lead to you uncovering innovative methods of improving numerous processes.

Rather than gathering these ideas via emails and phone calls, by installing whiteboards and 5S cuboids you’re creating a quick and accessible way for employees to share their thoughts and recommendations.

Monitor and measure

In order for you to know whether specific changes are bringing tangible results, you need to monitor daily activity and measure the outcomes. Key performance indicators could be reduced costs, increased revenue, shorter lead times, greater levels of safety, less waste, a higher quality of product, more reliable systems, and/or a rise in worker satisfaction.

Factors that can’t be measured as a quantity can instead be gauged in terms of quality. By capturing this quantitative data and qualitative feedback, you can show staff the impact their continuous improvements are having on the business, which will boost employee engagement even further.

Continuous improvement starts today

We’re here to help you make Lean work by applying continuous improvement across your business. To find out more about how our visual management specialists can support you, get in touch with our team on +44 (0)1482 296451 or fill in our contact form.