Visual Standards and Safety Walls

By

Rich Sutherland

·

3 minute read

By

Rich Sutherland

·

3 minute read

Health and safety in the workplace should always be given top priority, as it ensures that your people, vehicles, stock, machinery and wider infrastructure are protected against accident, injury and damage. However, getting H&S not only right but also consistent can be a very difficult task, as you need to know exactly what should be in place and where. In this blog we’re taking a look at health and safety in factory and warehouse settings and how Clarity’s Visual Standards and Safety Walls are helping to maximise it.

H&S at work: The key numbers

Statistics from the Health and Safety Executive for 2022/23 shed some light on the enormous impact gaps in health and safety can have on people. Despite health and safety systems and policies becoming more sophisticated with each year that passes, these figures show that significant improvement is still required.

- 561,000 non-fatal injuries at work according to self-reports (Labour Force Survey)

- 60,645 non-fatal injuries reported by employers (RIDDOR)

- 1.8 million workers suffered from work-related ill-health

- 135 workers and 68 members of the public died in fatal work-related accidents

- 35.2 million working days lost due to work-related illness and workplace injury

Types of health and safety equipment

There are many types of H&S equipment that need to be available throughout a workplace, especially in industrial settings where there are a wide range of potential hazards. Aside from PPE, the most common and important types of health and safety equipment include:

- First aid kits

- Eyewash stations

- AED (automated external defibrillator)

- Fire response

- Type D fire response (for flammable metals)

- Incident response (such as spill kits)

The importance of making safety equipment easy to access

From production lines and factory floors to warehouse loading bays and everywhere in between, it’s crucial that the right kind of safety equipment is not only available, but also easy to find, access and employ. There are multiple reasons for this, such as:

Employee safety: Ensure the safety and wellbeing of warehouse workers by giving them everything they need to respond to an emergency or incident very quickly. Time is of the essence – the shorter the response time, the more likely a serious injury or fatality can be prevented.

Compliance with regulations: Each sector has strict regulations and standards regarding workplace safety. Warehouses must comply with these regulations to avoid fines, penalties and legal liabilities. Ensuring that safety equipment is easily accessible is imperative.

Efficiency and productivity: If safety equipment is difficult to find or access, employees may waste time searching for it or be tempted to skip using it altogether. By making safety equipment easy to find, warehouses can promote efficiency and productivity by minimising downtime and disruptions caused by accidents.

Promoting safety culture: Making safety equipment visible and accessible sends a clear message to employees that their safety is a top priority for the organisation. This helps to foster a culture of safety where employees are encouraged to prioritise safe behaviours and look out for one another’s wellbeing.

What are Clarity’s Visual Standards and Safety Walls?

The team of Lean and visual management specialists here at Clarity have always provided bespoke tools that help workplaces to increase employee engagement and promote health and safety. A couple of years ago we decided to take our offering to a whole new level by combining multiple H&S products into a combined asset. The result was the Clarity Visual Standards and Safety Wall, which creates a prominent visual landmark.

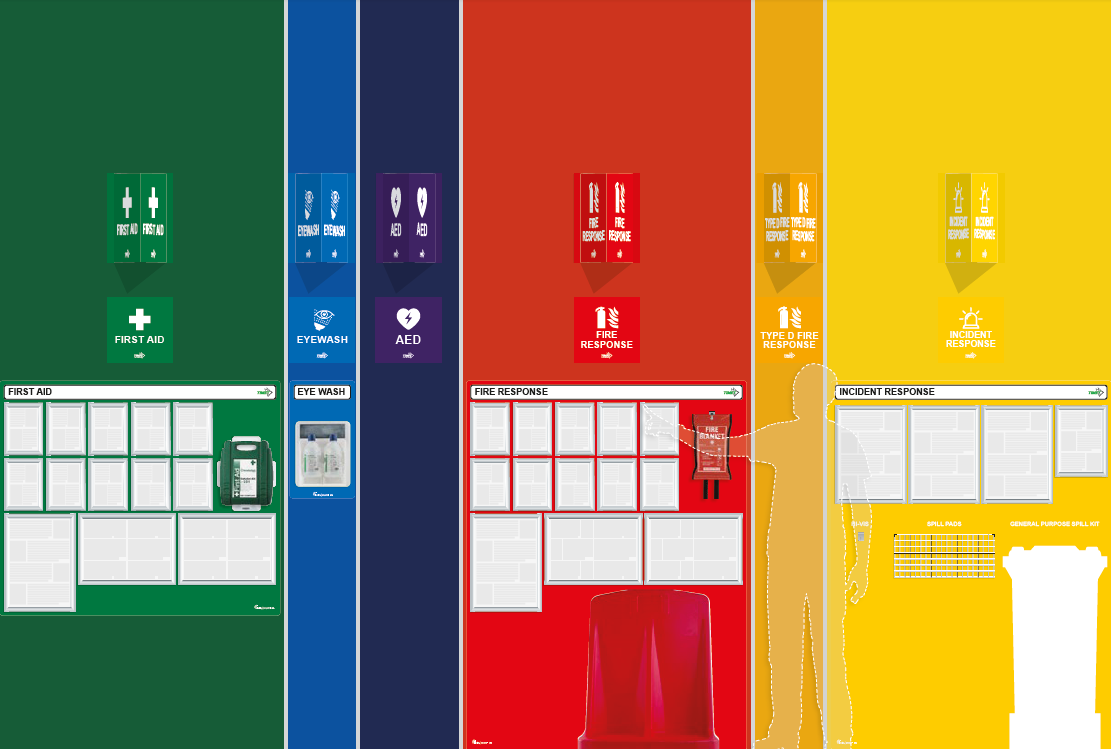

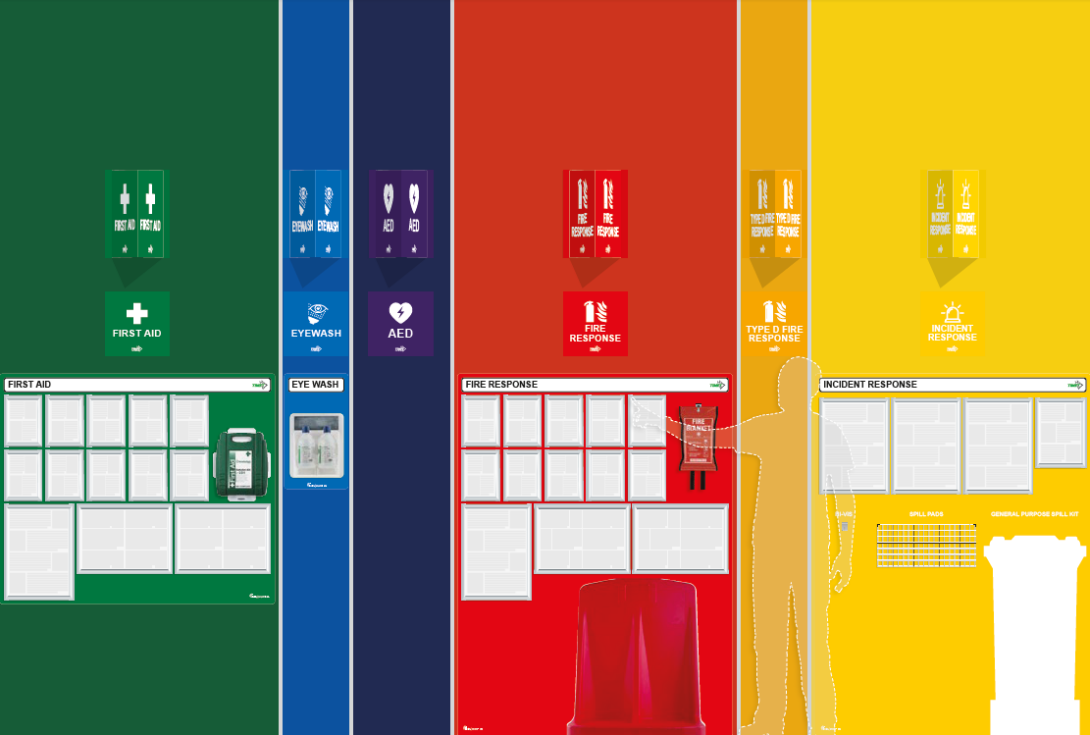

This prominent structure ensures that all team members can quickly and easily locate the health and safety equipment they require. As well as having large and clear lettering, these walls include a logical colour-coded scheme, from bright greens for first aid to vibrant reds for fire response. Any confusion or uncertainty is completely removed, which means that your workers can respond to an accident, emergency or incident with absolute clarity.

Your warehouse’s beacon of safety

Studies show that people remember 10% of what we hear, 20% of what we read, and 80% of what we see. This is because the human brain responds better to visual cues, which is why a visual safety wall that stands out, uses clear colour-coding and includes unambiguous icons (e.g. a heart for AED, flames for fire response) will instantly communicate safety standards to your workforce.

To ensure that your employees have exactly what they require, our Visual Standards and Safety Walls are designed, manufactured and installed according to the unique requirements of your working environments:

- Can be installed at tall heights to allow visibility

- Offers a systematic approach to workplace safety

- Customisable to your precise safety requirements

- Enhances efficiency by avoiding lost time searching for equipment

- Clear labelling and colour-coding prevents the wrong safety equipment being used

PPE Standards Wall

Clarity has also created a PPE Standards Board, which is designed to engage your workforce by providing a visual PPE checklist. A life-size illustration of the PPE required is set alongside a mirror, allowing the worker to check each item before entering a work area or using certain machinery. This innovative visual management asset is helping factory and warehouse workers to take responsibility over their personal safety and remain compliant at all times.

Maximise safety in your warehouse

Whether you’re interested in our Visual Standards and Safety Walls, our PPE Standards Boards or other unique visual management products that promote and enable safe working, we’re here to support your organisation through fully bespoke consultancy and design services.

Our Lean and visual management experts will visit your site to determine the best course of action, all you need to do is contact our team on +44 (0)1482 296451 or fill in our contact form to book your free consultation.