How do I choose the right flexible barrier for my factory?

By

Caleb Shaw

·

3 minute read

By

Caleb Shaw

·

3 minute read

When it comes to choosing a flexible industrial barrier, it may seem quite daunting because there is such a wide selection of barrier strengths and impact ratings available. There are barriers made of different types of plastics, and they all have different properties. The purpose of this article is to help you understand how you can choose what barrier you need to suit your factory.

Contents:

- What do I need the barriers for?

- What properties do the barriers need to have?

- How do I work out the Impact resistance?

- Do I need the barriers to be PAS 13 compliant?

- What budget do I have to install these in my factory?

- What are my options?

What do I need the barriers for?

There are a few different reasons you may want a barrier in your factory:

- Segregation of pedestrians and vehicles

- Protection from machinery

- To keep emergency routes clear

- To define pathways

- To protect assets from vehicle impacts

- To comply with Health & Safety regulations

Each of the above options, have different impact resistance requirements. For example, if you are simply using the barriers as a walkway, in an area where there are no forklift trucks, you can use the simplest specification of polymer barriers that are available. If you needed to protect pedestrians from heavy-duty forklift trucks however, you would need a higher specification of barrier to ensure you are going to keep your people safe. That is why it is important to consider the main purpose of the barriers you require in your factory. This then leads onto our next question.

What properties do the barriers need to have?

Hopefully, now you know what you need your barrier for, you will also have an idea of what properties the barrier will require. For example, do you need the barrier to be V0 fire rated or is there any chance that your production line configuration will change? In which case you should look at if the barrier system is modular etc. Here are some properties you should consider for your barrier:

- Fire rating – Do the barriers need to withstand high heats?

- Cold rating – Do the barriers need to be in a cold room environment?

- Recyclable or recycled?

- Scratch-resistant?

- Chemical-resistant?

- Modularity

- Durability

- Impact resistance – How much energy the barriers can take without deforming or breaking.

- PAS 13 compliant?

- UV-resistant

- Visibility – Yellow, Grey or Black

For more information on the differences between the main barrier suppliers in the UK, see the A-Safe vs Boplan vs MPM article here.

How do I work out the Impact resistance?

Once you have settled on the type of barrier you need for your factory, and you want to work out the strength rating for your factory. First thing you need to find out is what is the maximum weight of your forklift trucks and the maximum potential load that that forklift truck can carry so you can figure out the gross vehicle weight. You will also need to know the maximum speed that your forklifts travel to work out the amount of force in Joules (J) an impact would be. To work this out, use our impact calculator here.

So now you have worked out the impact rating in Joules, there is one thing left to check. That is the potential angle at which the FLT will hit the barrier. As you would expect if an FLT hit a barrier at 90°, it will do the most damage to it, but if the FLT glanced off it at an acute angle, then the actual energy will be significantly lower.

Do I need the barriers to be PAS 13 compliant?

Many of our clients in the UK, often go to A-safe to supply their barriers as they sponsored the creation of the PAS 13 specification in partnership with BSI as a code of practice for the implementation of safety barriers in factories. They are a trusted and well-recognised brand in the polymer safety barrier industry which is why many still choose A-safe. We do get asked however if our barriers are PAS 13 compliant.

The PAS 13:2017 document takes the form of guidance and recommendations and should not be quoted as if it were a specification. However, this does not mean that it should not be adhered to as a best-practice document.

This document outlines how safety barriers are used to promote the safe management of workplace traffic, safety barrier design and their uses in the workplace, how to calculate the kinetic energy of an impact, and the methods of testing that can be used.

So, if you are looking for a barrier that uses the advised standards of traffic flow management and impact resistance, then yes, our barriers are PAS 13 compliant, and we can provide the correct barriers for each application and circumstance within your warehouse.

What budget do I have to install these in my factory?

Another area that is crucial to consider when considering what barrier to go for, is the budget you have allowed for it. Many clients already have a rough idea of what it will cost, however some say that they have to get a quote before getting the budget for the job which is completely understandable. Either way, we can help you provide solutions that comply with the PAS 13 document whilst keeping under the budget that you require. Find out how much polymer barriers cost here.

What are my options?

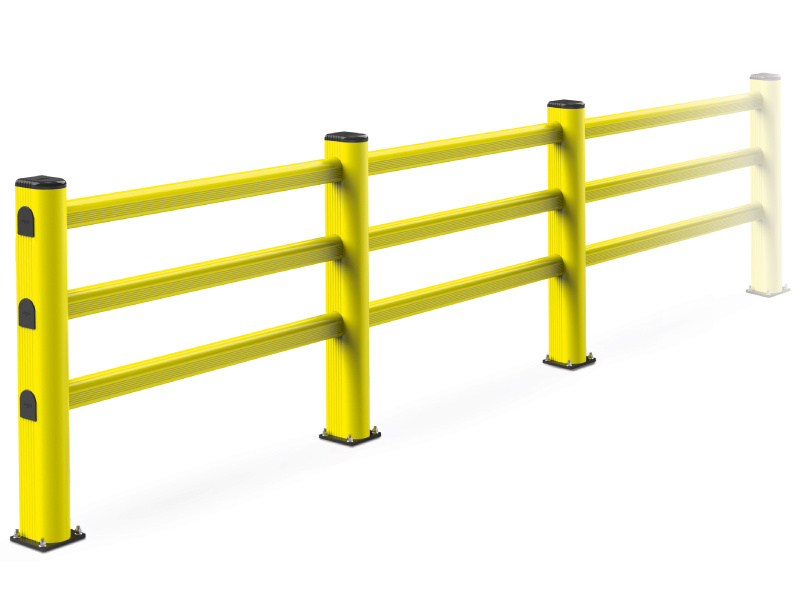

Every manufacturer of flexible industrial barriers also offers a range of complimentary features such as gates, detail finishes and even electronic tech to compliment it. At Clarity, we distribute the MPM range of flexible industrial barriers. MPM flexible industrial barriers are not the only manufacturer of flexible barriers, we have three or four different competitors in the UK, that offer a similar range.

The purpose of this article was to highlight what the options are for you in terms of the flexible industrial barriers you could choose from. You should now know what properties you need with your barrier, and what expectations you have set for your own site. Now you may require some assistance in picking the correct barrier to suit these requirements. Get in touch here to speak to an expert.