The Top 10 Reasons why Lean 5S Fails (and how you can stop it failing)

By

Damian White

·

4 minute read

By

Damian White

·

4 minute read

In today's competitive business landscape, implementing lean principles such as 5S methodology has become essential for organisations striving for efficiency and excellence. However, despite its numerous benefits, many companies encounter challenges that cause them to fall short in their 5S lean initiatives. In this article, we delve deep into the top ten reasons why 5S lean fails and provide insights on how to overcome these hurdles effectively.

Content:

1. Lack of Leadership Commitment

2. Insufficient Training and Education

3. Inadequate Employee Engagement

4. Poor communication channels

5. Lack of Regular Audits and Reviews

7. Inconsistent implementation across challenges

8. Lack of Reward and Recognition Systems

9. Failure to adapt to changing business needs

10. Inadequate resources and support

- Lack of Leadership Commitment

One of the primary reasons for the failure of 5S lean initiatives is the lack of strong leadership commitment. Without active involvement and support from top management, employees may not fully embrace the principles of 5S, leading to its ineffective implementation. It is important that managers reflect the attitudes they want to see in their staff, to ensure an example is set.

A quick way to ensure leadership commitment is ensured, is by aligning the 5S lean goals with the company mission and vision. It is much easier to implement and sustain a program like this, if it relates to the companies success, and tangible benefits can be seen.

- Insufficient Training and Education

Another common issue is the lack of adequate training and education on 5S methodology. To succeed in implementing lean practices, employees at all levels need to be thoroughly trained on the principles and techniques of 5S to ensure successful adoption and sustainability.

Training should include a mix of classroom learning and hands on training to ensure employees can see how the methodology will work for them on a daily basis. It is also important to get a trainer who can adapt the training to suit each business, as a simple certification, likely gets forgotten as the employee cannot see how that relates to his job role. When training is adapted, the business goals, current space, working practices and employees are all taken into account when delivering training.

- Inadequate Employee Engagement

Fostering employee engagement is crucial for the success of any lean initiative. When employees are not actively involved in the 5S process, they may resist change and fail to see the benefits of a clutter-free and organised work environment, leading to the failure of the 5S lean implementation.

The use of Lean Champions is a way to encourage employees to become engaged in the process, by giving them authority to act when they see something not aligned with their 5S goals.

- Poor Communication Channels

Effective communication is key to the success of 5S lean practices. Organisations that fail to establish clear communication channels to convey the importance and goals of 5S to employees may face challenges in implementation and sustaining the lean culture in the long run.

It may be useful to have a daily 5S check-in to ensure that ideas and progress is communicated clearly to the team.

- Lack of Regular Audits and Reviews

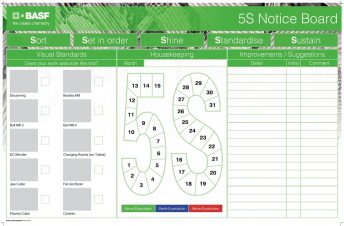

Without regular audits and reviews to monitor progress and identify areas of improvement, 5S lean implementations are prone to stagnation and eventual failure. Continuous monitoring and feedback mechanisms are essential for maintaining the momentum of lean practices.

Create a clear audit schedule aligned with your objectives for the program. This could be daily, weekly or monthly. Ensure that audits are carried out consistently, as consistency leads to a culture where the program is embedded.

- Resistance to Change

Resistance to change is a common barrier to the successful implementation of 5S lean methodology. Employees who are hesitant to embrace new work processes and organisational changes may impede the progress of 5S initiatives, hindering their overall success.

It could be useful to your employees to adopt a pilot scheme to show the potential success of 5S if it is rolled out across the entire company. It is also crucial that you discuss any fears or concerns that employees have with the program, as it is unlikely that change will happen, if they do not believe that it will work.

- Inconsistent Implementation Across Departments

Achieving consistency in implementing 5S practices across all departments is crucial for ensuring the effectiveness of lean initiatives. Inconsistent application of 5S principles can lead to disparities in productivity and efficiency, undermining the organisation's overall performance.

This can again be added into the daily check-ins that are implemented, to ensure the whole company is aligned on progress.

![Consulting Img [8]](https://clarityvm.com/hs-fs/hubfs/Consulting%20Img%20%5B8%5D.jpg?width=430&height=287&name=Consulting%20Img%20%5B8%5D.jpg)

- Lack of Reward and Recognition Systems

Recognising and rewarding employees for their active participation and contributions to 5S lean practices is essential for maintaining motivation and sustaining the momentum of continuous improvement. Failure to establish reward systems can demotivate employees and hamper the success of lean initiatives.

Find some rewards or initiatives that motivate your staff, and use them to encourage the use of the 5S program.

- Failure to Adapt to Changing Business Need

Organisations that do not adapt their 5S practices to align with changing business requirements may find their lean initiatives becoming obsolete and ineffective over time. Flexibility and agility are key to ensuring the sustainability and relevance of lean practices in dynamic business environments.

If you create a culture of continuous improvement alongside your 5S program, this will ensure that any change in business needs is easily met.

- Inadequate Resources and Support

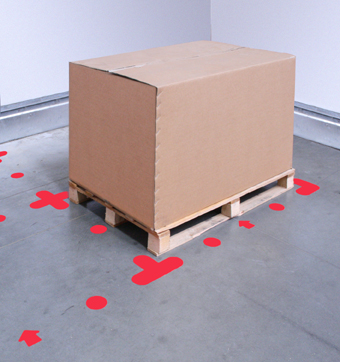

Lastly, insufficient allocation of resources and support for 5S lean initiatives can hinder their successful implementation. Organisations need to invest in the necessary tools, technology, and infrastructure to enable employees to effectively apply 5S principles in their daily work routines.

Often where 5S is thought to be a “less important” program, there is less money allocated to it, which is ironic as that can make it fail in itself. It could be useful to use pilot programs to counter this, as it demonstrates to senior management that the project can deliver very tangible cost savings and productivity benefits.

In conclusion, overcoming the challenges that cause 5S lean initiatives to fail requires strong leadership commitment, comprehensive training, daily check-ins and adequate resource allocation. By addressing these key areas, organisations can enhance the effectiveness of their 5S lean practices and drive sustainable improvements in productivity, efficiency, and quality.

If you are ready to start your lean journey, or need help sustaining it, get in touch here to speak to an expert.