The Top 5 Problems with using polymer barriers for airports

By

Damian White

·

2 minute read

By

Damian White

·

2 minute read

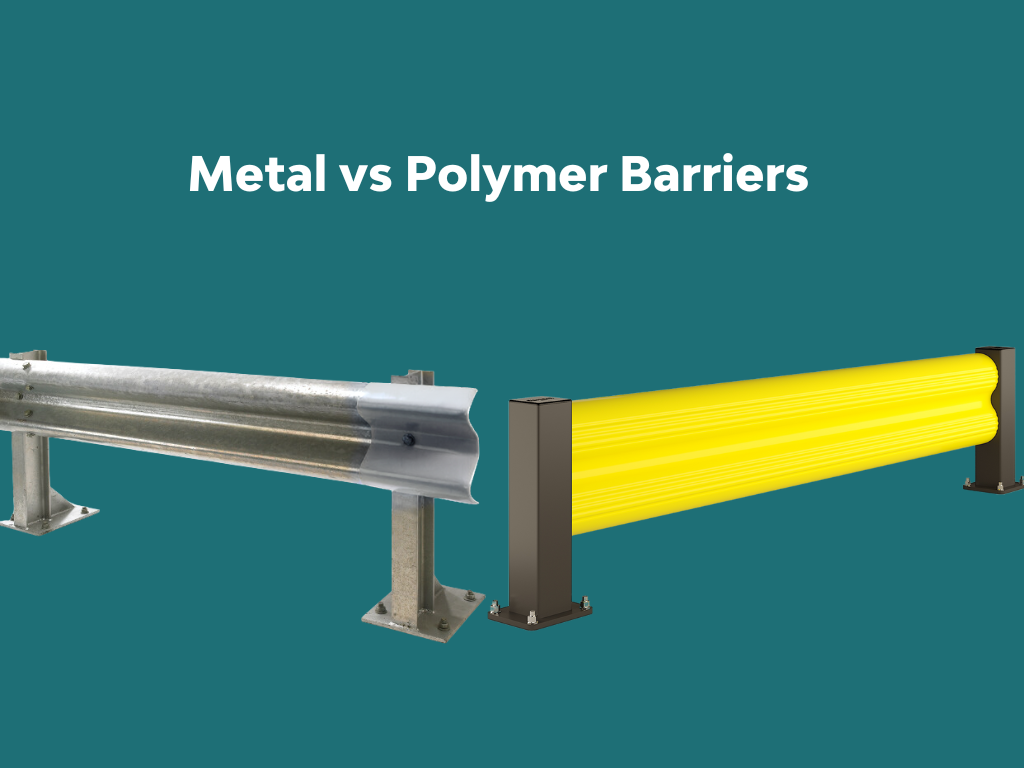

Polymer barriers are now used in virtually all industrial sectors, from warehousing to food production sites, and they offer many distinctive advantages over steel barriers. Airports present a different set of challenges compared to other environments.

If you are looking for polymer barriers for your airport project, then this article is for you. We will discuss the pros and cons of different types of polymers and the various challenges faced in airport projects.

The top five problems when using polymer barriers at airports are as follows:

- Frequent layout changes

- Exposure to UV light

- Exposure to harsh chemicals such as sky draw

- Risk of impacts by heavier vehicles than normally seen in typical industrial environments

- Fire risk

Frequent layout changes

Airports have seen a significant increase in traffic volume, especially since COVID. This has meant that most airports have had to adapt and modify to cope with the increased demand, resulting in changes to layouts. In most cases, this would mean the complete replacement of an existing barrier system to suit the new layout, as many barriers have a prefabricated design done offsite, which cannot be easily modified on-site. The exception to this is a modular barrier system, which can be modified, shortened, and even increased in length on-site.

Exposure to UV light

The very nature of an airport or apron means that the barriers could be exposed to UV lights all day. Many barriers are not designed or developed to be highly UV resistant and will degrade overtime. This can be seen at airports all over the UK where the barriers which originated as a bright orange colour are now somewhere between a pink and a white colour. This is because of a phenomenon known as photooxidation photooxidation occurs when the UV radiation is absorbed by the plastic causing it to break down.

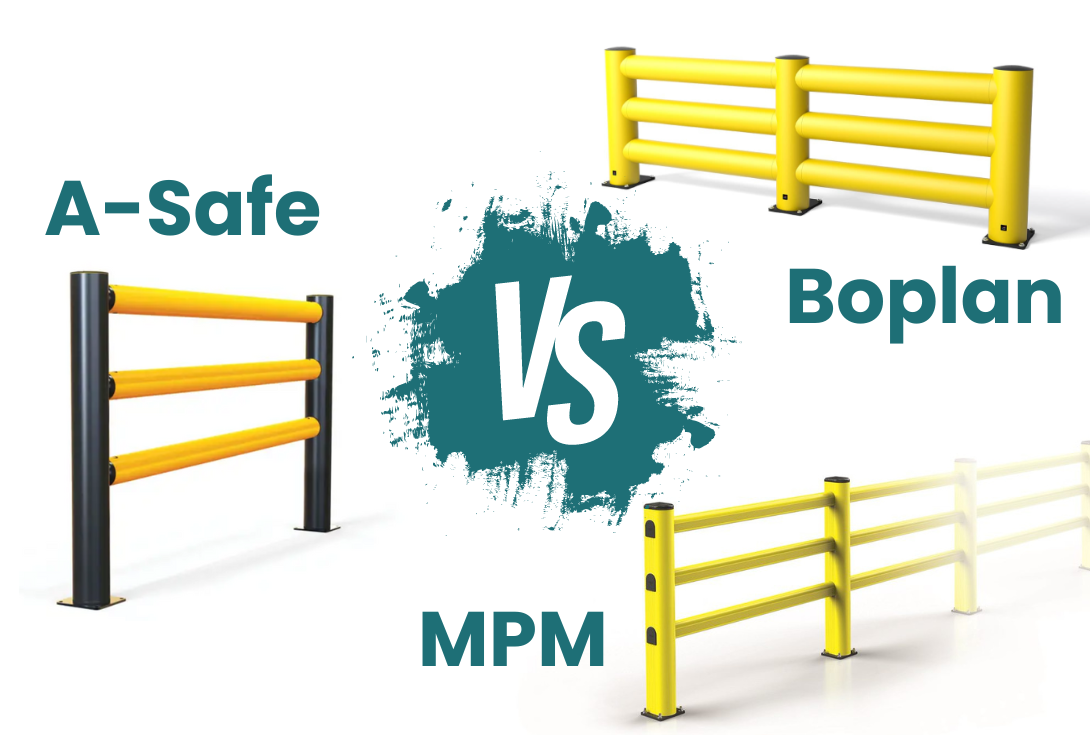

Plastics can be modified using UV absorbers, UV blockers and UV stabilisers however it is better to choose a polymer which has a higher inherent UV resistance initially. MPM PVC barriers have been developed to give exceptional UV performance.

Exposure to harsh chemicals

Anyone with experience working at airports knows how aggressive some of the chemicals required to operate an aircraft can be. Chemicals such as Skydrol, a hydraulic fluid used in aviation, require specialist PPE to prevent skin burns. Aggressive chemicals could also affect different polymer types. PVC barriers offer very good resistance to aviation chemicals.

Higher impact resistance requirements

Most polymer barriers are designed to absorb impacts from forklift trucks; however, airport barriers can be subjected to higher-speed impacts from tugs and baggage handling carts.

A quick inspection of the polymer barriers currently used at airports across the UK clearly shows that there is a need for a stronger and more robust option. The MPM Link 150/3 offers an impact resistance of over 52 kJ and is suitable for the most demanding applications.

Fire resistance

In the UK, we have experienced high-profile fires caused by the use of flammable building materials, especially with the Grenfell Tower disaster. Last year, with the horrific car park fire at London Stansted Airport, customers are much more aware of the need for fire-resistant products. Some types of polymer barriers offer no fire resistance and, with the help of a small ignition source, could contribute to another disaster. Choose a polymer barrier system with a V0 fire rating; this way, you know that passengers are protected beyond just the impact properties of the barrier.

What other factors should you consider when choosing the best pedestrian segregation system for your airport?

Once you have decided on the barrier type you wish to use, the next consideration is what technology is integrated into your designs.

Download our integrations guide here.

By using technology, you can reduce the risk of pedestrian/vehicle accidents. Barriers can be used as a holding area for passengers, with gates that can be unlocked using swipe cards, keypads, etc.

Interactive gates can lock when a luggage handling trolley approaches or when other vehicles are detected.

For help in choosing the best barrier for you, contact us here.