What does a "world-class" factory actually look like? The top 8 ways you can improve your facility to meet the expectations of the demanding client

By

Caleb Shaw

·

4 minute read

By

Caleb Shaw

·

4 minute read

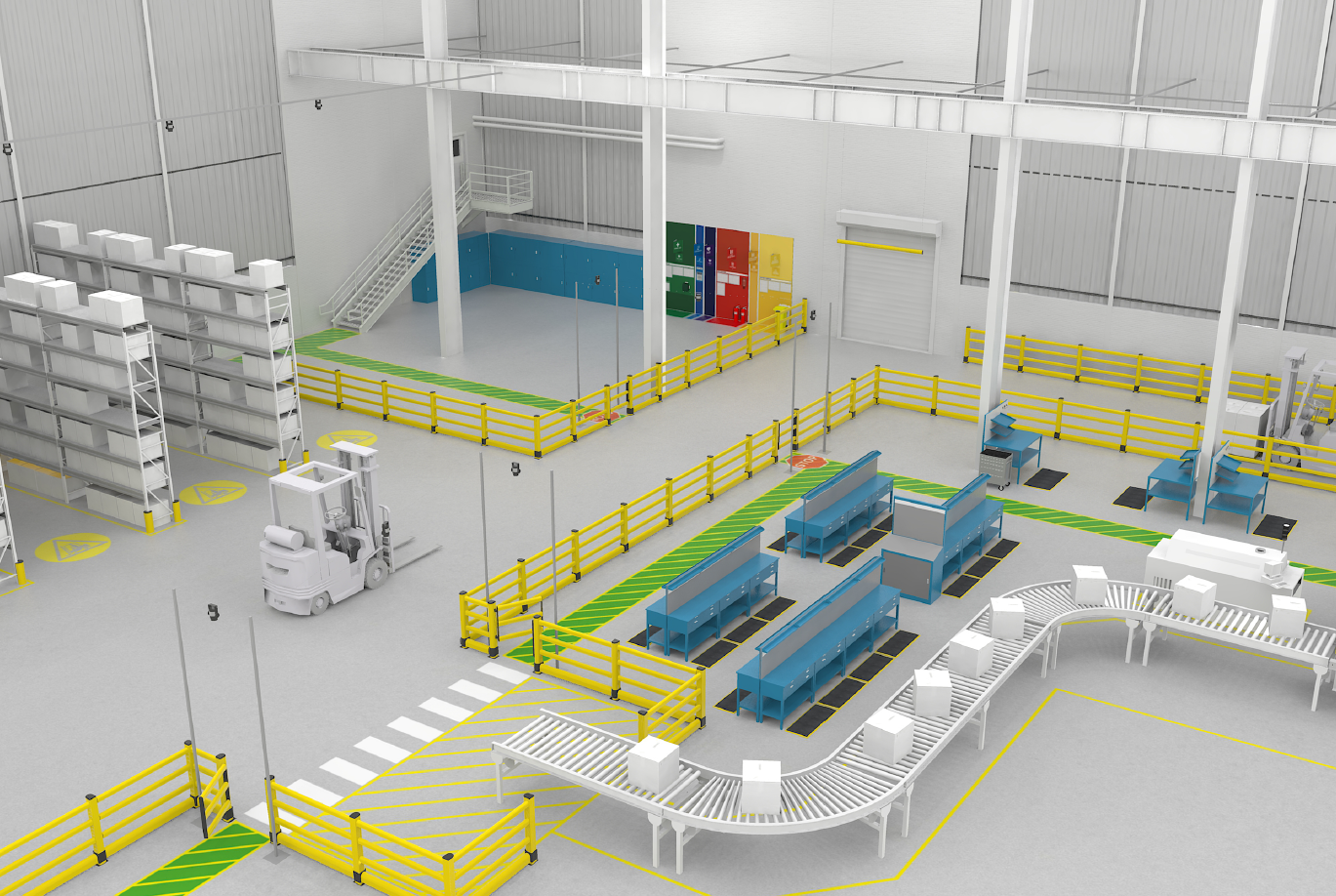

Every year at Clarity visual management meet with hundreds of factory, managers and site directors and one of the common themes we see across all manufacturing sectors, is the demand for a world-class facility, or simply a “Wow” factor for Visitors and employees. If this sounds familiar and you’re looking to implement some changes within your factory then welcome to this blog where we will run through a number of things that we’re seeing that make a huge difference to what would ordinarily be a normal factory.

By the end of this article, you’ll understand several ways in which you can implement changes to your factory which will not only give a “Wow” factor for Visitors but will improve or increase accident awareness, giving an overall safe site whilst making your people feel safe, appreciated and knowing how they can make a difference.

Employee retention

Covid caused a dynamic shift in the way workers chose who and where they worked. This gave a perspective into employees’ lives showing that perhaps money isn’t everything and better working conditions was a more desirable feature than being held to ransom by the highest bidder website, such as Glass Door and others. This change really exposed the weaknesses in some companies, leaving them behind whilst others were reaping the rewards of having a world-class manufacturing facility. No longer did workers feel they had to work in substandard conditions. And on top of all of that, the ageing population who were retiring early, were leaving a new generation of workers with a higher standard of expectations into the mix. Gone are the days where you just give an employee a job to do and they do it till it’s done. Today’s modern employees want to know the key company data, what they can do to make a difference and whether they are winning or losing. At Clarity, we have a simple visual formula for this, and we called it the 1-3-10 rule. This is a visual management system where anybody can see whether they’re at the relevant visual management display or board within 1 second, they can see if they are looking at the relevant department or measurement within three seconds and then within 10 seconds, they can see whether they are winning or losing. 1-3-10 boards have been in place in many factories for years prior to Covid, but it has become a prominent feature found in every world class manufacturing facility.

Raising safety awareness throughout site.

It is a sad fact that many factories and facilities don’t implement a significant safety awareness program until after an accident has happened. There is of course, a logical reason for this. There are costs associated with increasing accident awareness, and many companies do not have the time or resource to implement the changes needed to take their safety to the next level. Often, when we get called out to see a manufacturer or facility, it is because they have already had a near miss or an accident on site which has forced them to act, especially with companies on a global level. The reality is a safer culture is a culture which will pay dividends. So, what does safe actually Look like?

There are many ways to drive a safe culture throughout the business and the first impression always makes a huge difference. Here are 5 things we see in the world class facility that help drive a safe Culture:

- Lost Time Boards, especially digital or LCD displays really bring the data to life for visitors and employees. Every day matters.

- A visitor safety induction video for suppliers, customers, and visitors.

- A magnetic site map with permit to work located mark on it

- Clearly defined walkways throughout the factory, correct sign, posting or marking for Visitors.

- Pedestrian segregation from material handling vehicles (MHE’s) or Automated Guided Vehicles (AGV’s)

“But we’re doing all that already.”

If you’ve got this far into the article and feel like you’re already implementing the above to the best of your ability, but you’re not seeing the level of “wow” factor that you would like for your facility, let’s take this up a notch.

If you’ve already got a perfectly painted floor, the ideal walkways, the latest technology flexible barriers throughout your facility. Firstly, we would like to applaud you for your journey to World class. As you reach a certain level in this journey, there becomes a point when aside from the regular maintenance and upkeep of your facility there is not much else to do. Or is there?

To step up your game, another level, the obvious direction in which many world class facilities are going, is using the latest tech. Here are 3 examples for you:

- The latest technology is being used in world class facilities to take operating environments to the next level. There has been a shift towards slimmer profile, flexible impact barriers for segregating between material handling vehicles and people. 10 years ago, the latest flexible impact barriers, included large diameter round base rails with chunky posts, and this served, a great purpose in absorbing the impact without damaging the floor. Fast forward to today, with newer polymer technologies, manufacturers are able to produce flexible impact barriers to achieve the same impact rating with a much further reduced footprint. Whilst this is easier on the eye, it is also space saving initiative. In most factories space is a premium and the modern slimmer profile barrier can reduce space consumption without compromise.

- Another example of the latest tech trends being applied to factories is projected walkways. Traditional painted walkways will always have a place in the factory. However, a high traffic walkway, especially in an abrasive or clean room environment where it can wear away in a matter of months, a projected walkway provides a “Wow” factor and a long-term maintenance-free alternative to regularly repainting your walkways. These can be as simple as a dual, projected, parallel laser beam or a full colour LED projected walkway.

- If a projected walkway wasn’t already impressive enough, imagine a walkway which is interactive as per the example below. Another great use of LED projectors is to fix them to the crane which allows anybody in the facility to be aware of a moving load on a crane, as it gives a perimeter ring of light. This is usually 1-2m or up to 5m around the burden being lifted. An LED projector for a Crane will boost the “Wow” factor in any factory.

How can you implement “World-Class” in your facility?

So, you’re looking to make some improvements within your factory and maybe you’ve already started the journey. We will give you some ideas of additional changes you can make that improve your factory further.

Clarity is always helping customers get to that next level, so if you’re ready to make some big changes please feel free to reach out to us and we would love to help you on your journey. A “World-Class Factory” is a safe factory that retains their most talented employees due to their inclusive, supportive culture.

If you want to learn more about “World-Class” ideas, download our buyers guide here or reach out to us here.