What is a Visual Factory?

By

Alana Graham

·

2 minute read

By

Alana Graham

·

2 minute read

The term “visual factory” is becoming very commonplace, as it’s a way of increasing efficiency and productivity rates throughout your manufacturing facility. The question is, what exactly is a visual factory and how does it work? In this blog we’re sharing some useful insight that will help you to transform your workplace into a visual machine.

What is a visual factory?

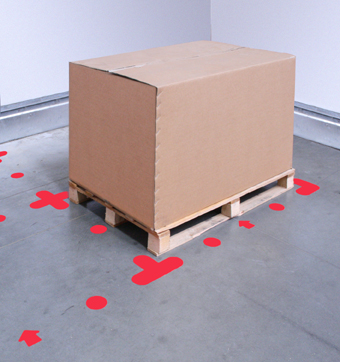

As the name suggests, a visual factory places strong focus on visual management tools. These can be in the form of whiteboards complemented by a range of magnetic overlays, as well as more advanced products like our 5S cuboids, PPE standards board and bespoke shadow boards. The mission of this Lean approach is to create a visual method of instantly communicating key information, which will benefit workflow and the day-to-day performance of your departments.

How do you create a visual factory?

An excellent place to start is by understanding the visual order enabled by 5S Workplace Organisation. 5S is the foundation of visual management, Lean management and operational excellence, as it facilitates a visual system that benefits all departments, processes and seniority levels. Here are the five elements of 5S:

- Sort: The first step is to sort necessary items from those that are superfluous. Any tools, equipment, signage and paperwork that’s not required within a work area should be removed, leaving only those that are useful.

- Set in order: The remaining tools and equipment now need to be allocated a logical and practical space. This can take a little while to achieve, as the key is to decide where everything should be stored as a means of maximising efficiency.

- Shine: This step is all about cleanliness but we’re not talking about a quick spring clean. Instead, a clear system needs to be created that holds regular cleaning, maintenance and inspections as top priorities.

- Standardise: Visual management is all about setting standards so that everyone remains on the same page and can accurately monitor performance and progress. Through the development of achievable standard practices and procedures, the above elements have the capacity to remain in place on a long-term basis. This takes us on to the final step…

- Sustain: Now that you have your standards in place, everyone needs to stick to them. This part of 5S is absolutely crucial, as it ensures that your visual system remains consistent and establishes longevity. In order to achieve this, all members of staff have to understand the importance of these new standards and play an active role in sustaining them.

What are the benefits of a visual factory?

A visual factory prevents data and information from being hidden away on clipboards and inside computer systems by making it highly accessible and easy to digest. As a result, you can expect the following benefits:

- Empowered employees who have the information they require at all times

- Minimal interruptions, ensuring individual focus is maximised

- Stronger workflow through greater efficiency

- Optimised product quality and production rates

- Higher levels of health and safety

- Tidy and organised workspaces

- Employee accountability for returning tools to their rightful place

- Smoother teamwork, which strengthens employee morale

Create a visual factory with Clarity

To book an initial consultation that will help you to unlock the power of visual management, get in touch by filling in our contact page here.