A Step-by-Step Guide to installing Mighty Line Tape

By

Alana Graham

·

3 minute read

By

Alana Graham

·

3 minute read

So, you've bought some Mighty Line Tape from us. How should you install to ensure it lasts as long as possible?

Watch the Video below, or read on...

A Step-by-Step Guide to Installing Mighty Line Floor Marking Tape

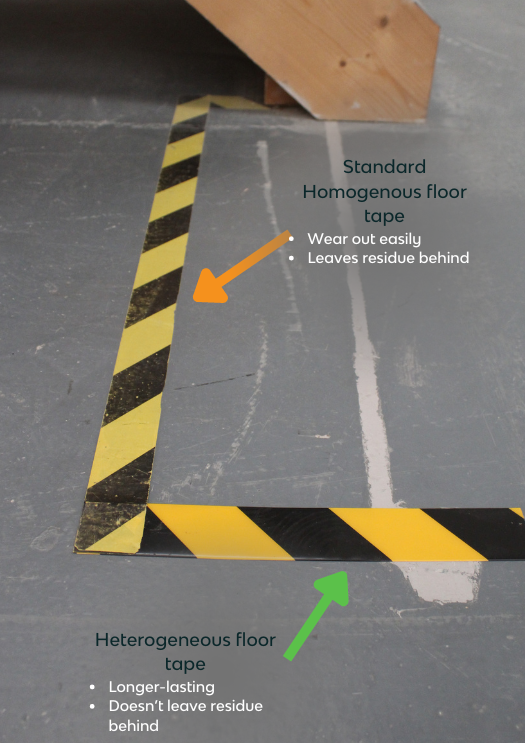

To meet health and safety standards, permanent aisles and passageways in manufacturing or storage environments must be clearly marked. Mighty Line floor tape offers a simple and effective solution to ensure compliance with regulations, while also helping to maintain an organised workspace. The tape is easy to install and remove, making it versatile for various environments and needs. Below, we share some helpful tips for installation and ensuring your floor tape lasts.

Before purchasing, we always recommend testing Mighty Line floor tape with our free sample kits to ensure it suits your specific flooring type. Concrete and other surfaces can vary, so this ensures the best results. Request your free samples here.

-

Prepare the Surface: Before installing Mighty Line floor tape, ensure the floor is clean and dry to guarantee the tape adheres properly. Avoid using acid-based cleaners, as these can leave residues on the floor that reduce adhesion. If you need to use an acid-based cleaner, neutralise it with baking soda. Alternatively, we offer a safe, non-chlorine-based all-purpose cleaner to effectively prepare your floors. For heavily soiled areas, industrial scrubbers may be required.

-

Dealing with Moisture: If the tape does not adhere properly or peels off shortly after installation, moisture from the floor may be affecting its bond. To check for moisture, place a 2'x2' square of industrial stretch wrap on the floor and seal it with duct tape. After a few hours, if moisture is visible on the wrap, there is moisture in the floor. To address this, apply a concrete sealer to the affected areas. We recommend using V-Seal 101 or 102 and spraying the edges of the tape after installation for added protection.

-

Oily Floors: Mighty Line floor tape may not stick well to oily floors. For areas with oil or grease build-up, we recommend applying an oily floor primer, such as Tri-Chem's Tri-Oil Stop, before installation. This product is designed to prevent oil migration and ensure the tape adheres correctly. More information about Tri-Oil Stop can be found here.

-

High-Traffic Areas: In areas with heavy machinery or foot traffic, consider using Mighty Line Dots or Segments. These can be arranged to create a line of individual dots and/or segments that are easily replaceable. Explore our range of 5S products for similar applications and uses.

-

Creating Neat Corners: Achieve a professional look by mitring the corners of your floor tape. To do this, overlap two strips of tape at the corner by a couple of inches, then cut both layers from corner to corner. Discard the excess tape and press the cuts firmly together to create a seamless corner.

-

Repairing or Replacing Damaged Tape: To replace damaged tape, simply remove the affected area and apply new tape over the old. Use the mitre technique mentioned above to cut through both the old and new layers and remove any excess for a smooth, clean finish.

-

Aisle Width Recommendations: The width of aisles should be determined by their intended use. For instance, aisles used by large equipment should be wider than those designated for pedestrians or workers. OSHA suggests that aisleways should be at least 3 feet wider than the largest equipment, or a minimum of 4 feet wide.

-

Choosing the Right Size of Floor Marking Tape: Mighty Line floor tape is available in 2, 3, 4, and 6-inch widths, making it suitable for most facility areas. Other 5S floor tape products are also available in a variety of sizes to cater to different needs across your site.

-

Outdoor Use: While Mighty Line is not specifically warranted for outdoor use, it can be applied outdoors with caution. Be mindful of snowploughs and salt, which may damage the tape. Detailed instructions for outdoor use can be found here.

-

Additional Tips for Maintaining Floor Tape:

- Avoid dragging skids and pallets across the tape.

- Keep harsh acids away from the tape, as they can weaken the adhesive.

- Always try a free sample kit to ensure the tape works in your specific environment.

- OSHA Colour Code Guide: The OSHA and ANSI Z535.2 Safety Colour Code system designates colours for specific safety purposes. For example, yellow is used for caution, red for danger, orange for warning, green for safety, and blue for notice. Mighty Line floor tape comes in a variety of colours, patterns, and shapes, allowing you to meet these safety standards and enhance workplace safety.

Learn more about OSHA guidelines here.