Warehouse floor line marking cost and pricing guide

By

Damian White

·

5 minute read

By

Damian White

·

5 minute read

We understand that painting your warehouse or factory floor is a huge decision. We aim to empower you with line marking cost information that will help you budget for your project.

As you consider defining areas of your warehouse with a specialist coating, this cost and pricing guide will help you develop an initial budget and plan for the ownership costs associated with each type of floor line marking.

Here at Clarity, we have been supplying floor marking paints for over 10 years. Warehouse floor line marking is part of our workplace organisation products. Our warehouse floor marking products consist of:

- Epoxy or MMA based paint systems

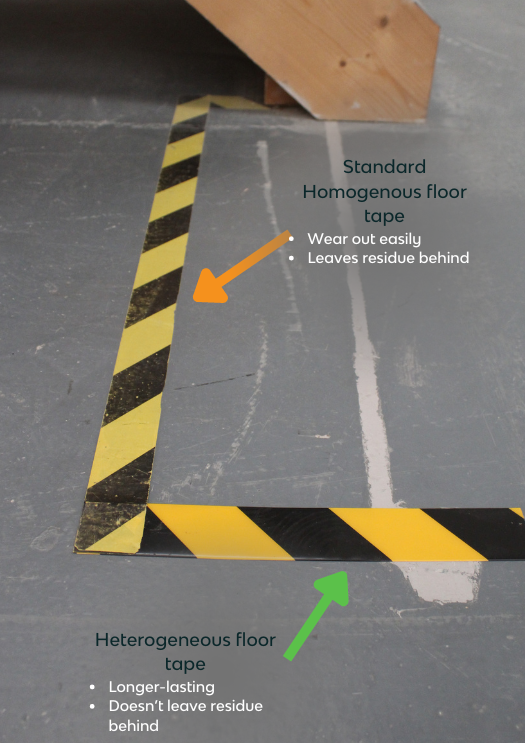

- Mighty Line floor marking tapes

- LED projected floor marking lines

- Laser projected floor marking lines

Cost of warehouse line marking: The top 4 things to consider

- Cost of the product

- Cost of install

- Cost over 5 years

- Running costs and reconfiguration costs

By the end of this article, you will have a better idea of what each warehouse line marking system will cost you and how long you can expect them to last.

First, let's take a look at the initial cost of Paint, Mightyline tape, lasers, and LED projectors to get an idea of how much to budget for each.

Then, we'll look at the long-term cost associated with each type of warehouse line marking

Epoxy Paint, Mightyline Tape, Lasers and LED projector costs

Epoxy Paint: Initial Cost

The biggest challenge with epoxy painted warehouse lines is the variability in cost, a competent maintenance team with quality, clean and dry floor could paint this for the lowest cost however, if the existing floor has existing marks, is not perfectly clean or is not perfectly dry - the costs spiral.

There are two type of epoxy paint installation packages:

- Self-installation (paint it yourself)

- Professional contractor installation

Let's take a look at both to learn more.

Epoxy painted warehouse lines; Self-Installations

A self-installation package would simply be that the customer takes delivery of the epoxy paint.. The customer takes it from there.

The obvious advantage of painting your own epoxy paint warehouse lines is what you'd save from reducing the installation cost. However we do not recommend self-installations. In fact we strongly recommend that you work with a professional installer.

The price of the paint is determined by two things: the type of epoxy and the size of the lines to be painted.

- Standard floor coating - typically up to 2 coats - for light to medium duty

- High build heavy duty epoxy - typically 2-3 coats

A standard floor coating epoxy will likely cost you £50-100/5 Litres.

A 5 Litre epoxy paint will typically cover 100M @0.25mm thickness.

A High build premium line marking tape will likely cost £150-250/Litre

A 5 litre epoxy paint will typically cover 50M @0.5mm thickness.

These costs do not allow for cost of hire of painting equipment, surface grinding equipment, masking up and removal of waste from site.

Epoxy painted warehouse lines; Professional Contractor Installation

The overwhelming advantage of a turn-key installation is convenience.

Resources are available to teach managers how to paint their own warehouse line markings, but the vast majority of warehouse managers prefer to leave the installation of the line markings to a professional flooring contractor. There are many advantages of this including:

- Top advice to recommend the best epoxy paint for your specific requirements.

- Thorough surface preparation involves grinding back the top coat of concrete to expose a good surface for the paint to bond to.

- Extraction of dust from surface preparation

- Optimised painting conditions: a good contractor will tell you if the concrete/temperature conditions will affect the life span of the paint.

- No spills or slops.

- Quickest turnaround time.

- No expensive tool hire required.

- Removal of waste from site

The factors affecting the price are as follows:

- Cleanliness of current floor

- Finish of existing topcoat (How much needs to be ground back)

- How much can be painted in one go - as opposed to piecemeal to work around shift patterns

- Access - are specialist lifts required?

- Temperature in area to be painted. This affects the curing time which affects when the second and/or third coat is required

Mighty Line floor marking tape: Initial Cost

There are two type of Mighty Line line marking tape installation packages:

- Self-installation (install it yourself)

- Clarity installation

Let's take a look at both to learn more.

Mighty Line tape warehouse lines; Self-Installations

A self-installation package would simply be that the customer takes delivery of the tape.. The customer takes it from there.

Self installation of Mighty Line tape is the most common choice for most customers, as long as the floor is clean and dust-free, you can expect a 3 year service life from the tape.

The price of the tape is determined by two things: the width of the lines and the whether it is standard or anti-slip

- Standard 50mm wide Mighty Line floor tape is £90-120/33m roll, A 100mm wide roll will cost you £120-£140/roll

- Mighty Line anti-slip tape will cost an approximately £40/roll more.

Mighty Line tape warehouse lines; Clarity Installation

Some customers prefer us to install the Mighty Line tapes for them.

While we offer install instructions on how to install Mighty Line warehouse line markings, some clients prefer to leave the installation of the line markings to a professional tape laying. There are many advantages of this including:

- Specialist equipment for checking the floor is clean and dry enough (and the right temperature.

- Specialist tape laying equipment, including robots in some cases.

- ensures maximum longevity of the lifespan

- Removal of waste from site

The typical cost of a contractor installing the Mighty Line tape for you will vary from £10-50/metre, the factors which affect the price are as follows:

- Access to site - a clear run is needed

- Cleanliness of existing floor

LED Projected lines: Initial Cost

There are two LED projected warehouse line installation packages:

- Self-installation (install it yourself)

- Clarity installation

Let's take a look at both to learn more.

Epoxy painted warehouse lines Self-Installations

A self-installation package would simply be that the customer takes delivery of the epoxy paint.. The customer takes it from there.

The obvious advantage of painting your own epoxy paint warehouse lines is what you'd save from reducing the installation cost. However we do not recommend self-installations. In fact we strongly recommend that you work with a professional installer.

The price of the paint is determined by two things: the type of epoxy and the size of the lines to be painted.

- Standard floor coating - typically up to 2 coats - for light to medium duty

- High build heavy duty epoxy - typically 2-3 coats

A standard floor coating epoxy will likely cost you £50-100/5 Litres.

A 5 Litre epoxy paint will typically cover 100M @0.25mm thickness.

A High build premium line marking tape will likely cost £150-250/Litre

A 5 litre epoxy paint will typically cover 50M @0.5mm thickness.

These costs do not allow for cost of hire of painting equipment, surface grinding equipment, masking up and removal of waste from site.

Contractor line painting Packages

The overwhelming advantage of a turn-key installation is convenience.

Resources are available to teach managers how to paint their own warehouse line markings, but the vast majority of warehouse managers prefer to leave the installation of the line markings to a professional flooring contractor. There are many advantages of this including:

- Top advice to recommend the best epoxy paint for your specific requirements.

- Thorough surface preparation involves grinding back the top coat of concrete to expose a good surface for the paint to bond to.

- Extraction of dust from surface preparation

- Optimised painting conditions: a good contractor will tell you if the concrete/temperature conditions will affect the life span of the paint.

- No spills or slops.

- Quickest turnaround time.

- No expensive tool hire required.

- Removal of waste from site

The typical cost of a professional installer painting the lines for you will vary from £25-350/metre.

What are the pitfalls of a laser warehouse line marking system?

A laser projection system offers the highest efficiency of the two projector types; however, it is still an energy-consuming light source, although only 15 W. Most Chinese laser systems have a warranty of just nine months, while the Clarity laser projection system has a two-year warranty. Like LED projectors, a laser line marking system will not work very well in very bright warehouses or external conditions. Typically, for a 100-meter linear projection, you will need around five laser projectors. In general, lasers are only available in green or red.

Want to see what a laser or LED projector system will look like in your warehouse? - Contact us today for a free consultation and trial.