Warehouse line marking: Is Epoxy Paint really the best option for you?

By

Damian White

·

6 minute read

By

Damian White

·

6 minute read

Choosing the best line marking paint is difficult because there are a wide variety of options available. Now you are at the point of making a decision, and you are considering using epoxy for your application.

Here at Clarity, we have been supplying floor marking paints for over 10 years. Warehouse floor line marking is part of our workplace organisation products.

Epoxy line marking paint is a two-component paint system designed to be applied directly to your warehouse floor.

Trying to find unbiased and honest information about the best warehouse line marking options for you is difficult. Technical data sheets are helpful, but they often don’t go into detail about the product.

We wrote this article so that you could make an educated decision on the best option for you. In this article, we will discuss:

- Why Epoxy floor paint is often used

- What other options are available?

- How do the other options compare in price?

- What are the advantages of each option?

- What are the disadvantages of each option?

By the end of this article, you will have a better idea of which warehouse line marking system is best for you.

What are warehouse line markings?

Warehouse line marking is used in most warehouses and factories across the UK. It is utilized to demarcate machinery, safe areas, walkways, fire exits, pallet spaces, and much more. Typically, warehouse line marking consists of color-coded paint or tape applied in straight lines, often as part of a workplace organisation program.

Why is Epoxy paint often used?

Once cured, epoxy is an extremely strong product. It is used for bonding components on airplanes and has excellent resistance to chemicals. When applied properly for warehouse line marking, epoxy paint can last over 10 years and has excellent resistance to fading from UV light. Epoxy paint can be applied easily with standard equipment but can take several days to fully dry.

What else can be used for Warehouse line marking?

While epoxy can be regarded as one of the most durable paint systems for warehouse line marking, it is not the only one. It is possible to use MMA, Polyurethane and even UV light curing paint systems. Each different paint system offers a range of Benefits and challenges.

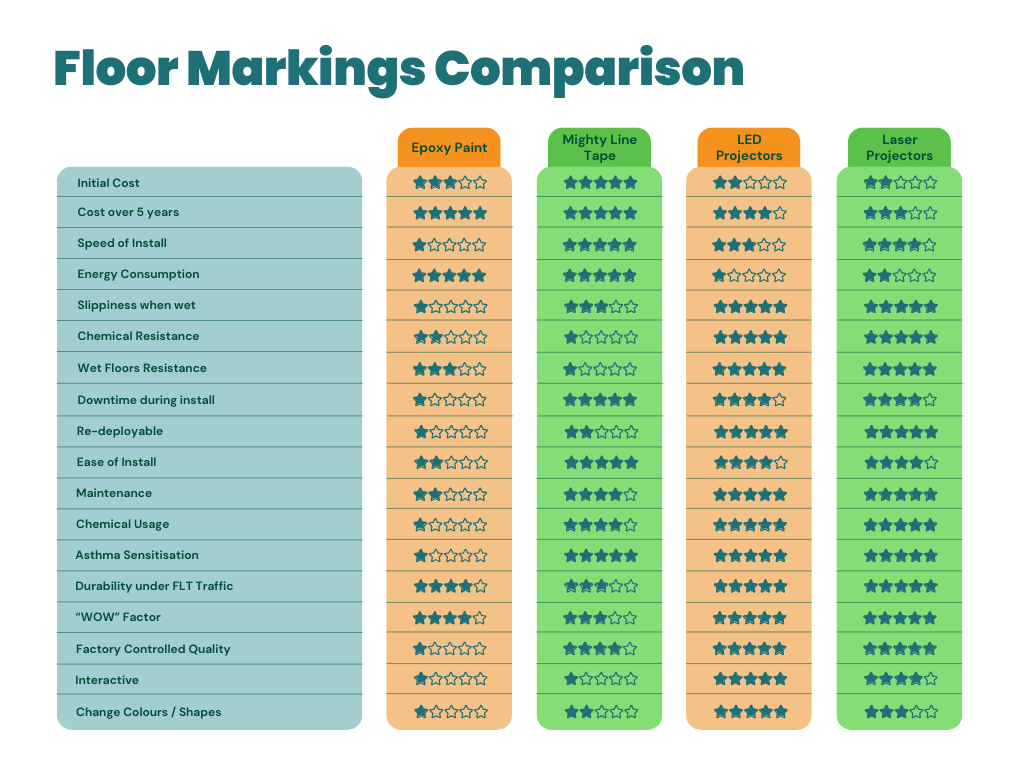

Paint is not the only option for warehouse line marking, here at clarity we offer:

- Epoxy paint Systems

- Mighty Line floor marking Tapes

- LED projected line markings

- Laser line markings

How do each of these options compare In cost?

When we compare the cost of epoxy line marking paint to tape or a projected solution, there are many additional factors to consider. For example, if you choose to use epoxy paint for marking in your factory, you could simply purchase a pot of epoxy paint and do it yourself. Typically, this option would be expected to last only between one and two years, whereas a professionally applied epoxy can last over 10 years. The key difference between a professional painter and a DIY painter is their fundamental knowledge of the paint system and the surface preparation.

What are the advantages of using epoxy paint for your warehouse line marking?

Epoxy paint is usually used for line marking in factories due to the extreme durability of the system. It is easy to apply, gives a good finish, and is relatively low-cost for the lifespan of the product. These systems can be used in very bright conditions, in wash-down/wet areas, and even externally with limited impact from cleaning chemicals, etc.

What are the advantages of Mighty Line floor marking tape?

Not every company is ready to paint their floors because this becomes a semi-permanent modification to your warehouse. If you are not prepared for a permanent layout within your warehouse, then Mighty Line floor marking tapes are an excellent option for you. While the floor needs to be clean and dry for the tape to adhere well, they do not require the same level of abrasion and surface preparation as epoxy paint.

Mighty Line floor tapes can be applied in seconds and can outlast some paint systems. Mighty Line floor tapes offer the lowest overall cost, the fastest installation speed, and are available in stock in a wide variety of colors and widths. You can expect a lifespan of five years in normal use with Mighty Line tapes.

What are the advantages with an LED projected warehouse line marking?

LED projected line markings represent the latest technology for projecting lines in your warehouse. These projected lines remain unaffected by heavy traffic, aggressive chemicals, and wet or oily floors. Depending on floor-to-ceiling heights and lux levels in factories, LED projected lines can be the most cost-effective option for a projected solution.

If your warehouse or factory layout might change over the next five years, an LED projector system is completely portable and can be quickly and easily adjusted to adapt. LED projected lines are available in virtually any color, although some colors are harder to project than others—see the article on the top five problems with projected solutions. LED projected warehouse line markings perform well regardless of floor conditions or traffic levels in your warehouse. They also work better in less than optimal lighting conditions, adding a "wow" factor to any warehouse.

What are the advantages of a laser projection?

Here at Clarity, we have installed numerous laser projection systems across the UK. Laser projectors offer the highest efficiency and brightest projection for most factories. Similar to an LED projector, the laser projection systems are also completely portable and can be adapted to suit a changing layout. For warehouses wanting long lengths of projected lines, a laser projection system could offer the lowest overall projection cost depending on the floor-to-ceiling heights, as an optimal laser projection can project up to 22 linear meters per single laser projector.

Laser projectors will work in virtually any warehouse, regardless of the current floor coverings or traffic. Laser warehouse line markings are perfect for factories using strong detergents and chemicals to clean the floor and where there is a risk of standing water.

What are the disadvantages of each floor line marking type?

What are the downsides to an epoxy paint system?

An epoxy paint system forms a very hard-wearing, durable coating; however, it is a wet lay system and is therefore highly dependent on proper surface preparation and correct ambient conditions for the paint system to cure. If any of these factors are not correct, the paint system will either not cure properly or simply flake away after curing.

Epoxy paint systems are heavily dependent on perfect surface preparation to achieve optimal service life; however, the paint system will only be as good as the surface it is bonded to. If this is not perfect, premature failure can be expected. Epoxy paint systems will not cure below certain temperatures, whether that is the ambient temperature or the concrete floor it is being applied to.

The surface preparation required and the curing mechanism for an epoxy paint system may mean that areas of your warehouse will be out of action while the paint system cures, which can take from 48 to 72 hours. Operators and pedestrians can become sensitized to epoxy, causing breathing issues until the paint is fully cured, especially in areas with inadequate ventilation. If you have decided that a paint system is what you really want but the slow cure is a problem for you, then you could consider other paint systems such as MMA or UV curing, which will speed up this process significantly.

Ready to paint your floors? Let us take away the stress with a budget cost for your warehouse—contact us here.

What are the downsides to Mighty Line floor Tape?

Mighty Line floor tapes have seen great success in the United States and now in Europe, but they do have some downsides. As with any floor tape or paint system, the adhesive mechanism is only as good as the surface you are bonding to, so it needs to be a clean, dry floor. Another issue with using Mighty Line floor tapes is that they can become damaged if a pallet or sharp, heavy object is dragged across them. This problem is minimized with the smooth edge profile but will not eliminate the issue altogether.

Mighty Line floor marking tapes can be affected by harsh cleaning chemicals and are not suited for warehouses where there is standing water, as this could compromise the adhesion. The floor temperature also plays a role in the effectiveness of the adhesive on a floor marking tape. These tapes should not be used in factories and warehouses with a floor temperature below 10°C at the point of application. If the floor temperature drops below 10°C after application, this is not a problem.

Need to test some for yourself? Not a problem!

What are the downsides to an LED projected floor marking?

LED projected floor markings have seen an increase across the UK in recent years; however, they are not suited to every warehouse. To create a 100-meter-long line may require up to 20 projectors, depending on the lux level and the floor-to-ceiling height. This means that an LED projected solution could become quite a costly option. In factories where the lux level is over 1000, it may not be feasible to use a projected solution due to the surrounding brightness. Some projectors have a warranty of up to 5 years; however, a budget projector may only last six months with continuous use.

Depending on the power of the projectors used, an LED projected solution also incurs the highest ongoing operational costs as they are a power-consuming light source. While some LED projected lines are just 25 W, depending on your warehouse, it may be necessary to use projectors up to 300 W.

Ready to see what an LED projection system will cost you? Contact us here to get a budget estimate and see an LED working in your warehouse.

What are the pitfalls of a laser warehouse line marking system?

A laser projection system offers the highest efficiency of the two projector types; however, it is still an energy-consuming light source, although only 15 W. Most Chinese laser systems have a warranty of just nine months, while the Clarity laser projection system has a two-year warranty. Like LED projectors, a laser line marking system will not work very well in very bright warehouses or external conditions. Typically, for a 100-meter linear projection, you will need around five laser projectors. In general, lasers are only available in green or red.

Want to see what a laser projector system will look like in your warehouse? - Contact us today for a free consultation and trial.